Event recorder for diesel-locomotive shunter RPDA-T and main-line diesel-locomotive RPDA-TM

|

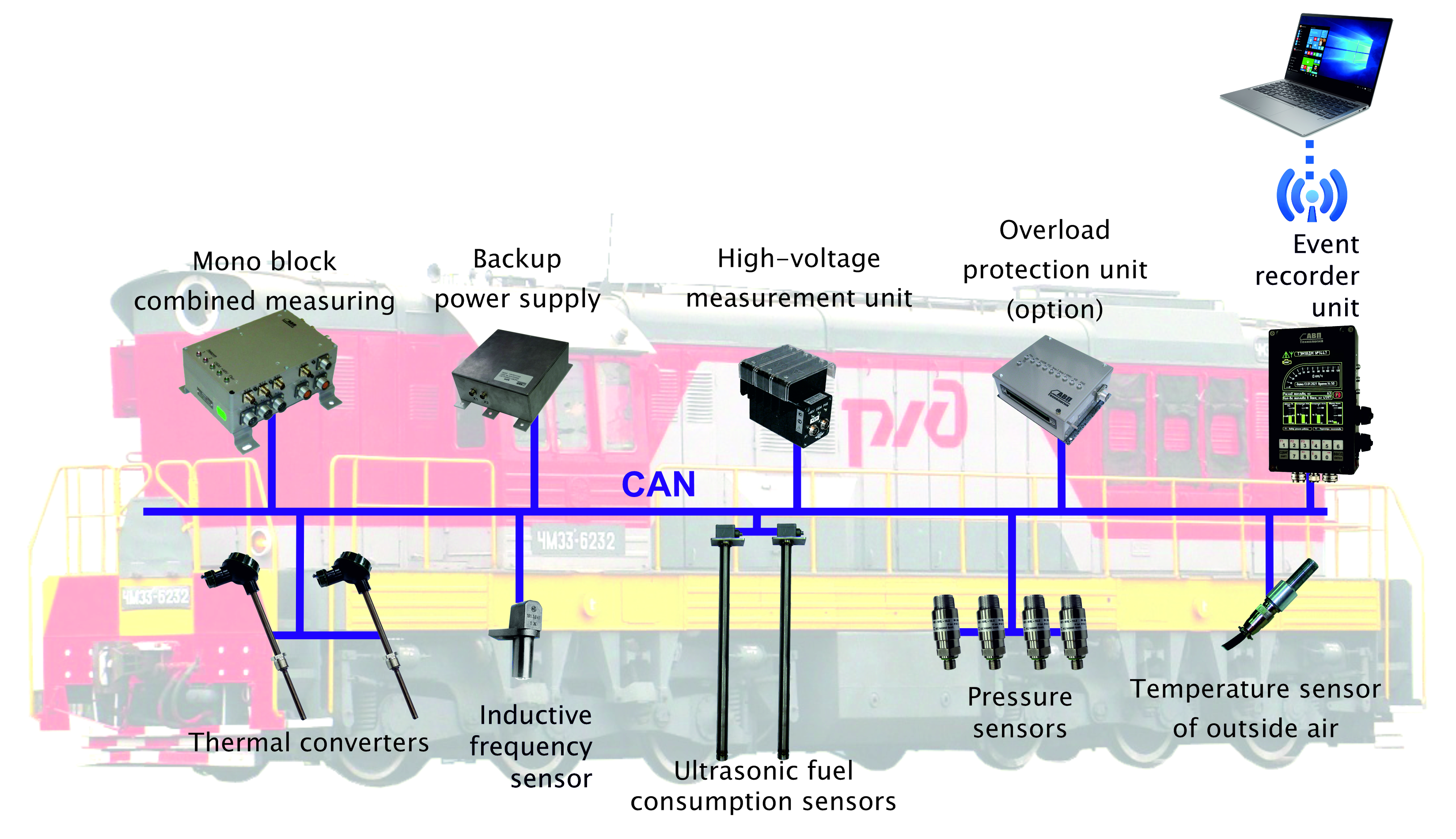

Event recorders RPDA-T, RPDA-TM are designed for automatic measurement, recording and processing of data about the movement and the operation of the locomotive; the goal is to control and registration work data and fuel consumption, to control the technical condition of shunting locomotives series ChME3, TEM2, TEM7, TEM9, TEM14, TEM18, TEM23, TGM6 and main-line locomotives 2M62, 2TE116, 2TE10, 2TE116, 3TE28, 3ТЭ25К2М, 3ТЭ25К3М, ТЭП70. System can be easily adjusted to other locomotive series. Operation features of RPDA-T, RPDA-TM system

Event recorder RPDA-T, RPDA-TM is data acquisition system. All measured data, including fuel consumption and locomotive operation data, can be record on a special flash-drive, named “RPDA cartridge”, and also can be send via GSM/GPRS channel. Decoded data is a basis for future analysis: 1. Fuel consumption and locomotive operation data

2. Technical condition state of the locomotive. 3. Summary of the use of locomotives. 4. Summary of engine drivers work. |

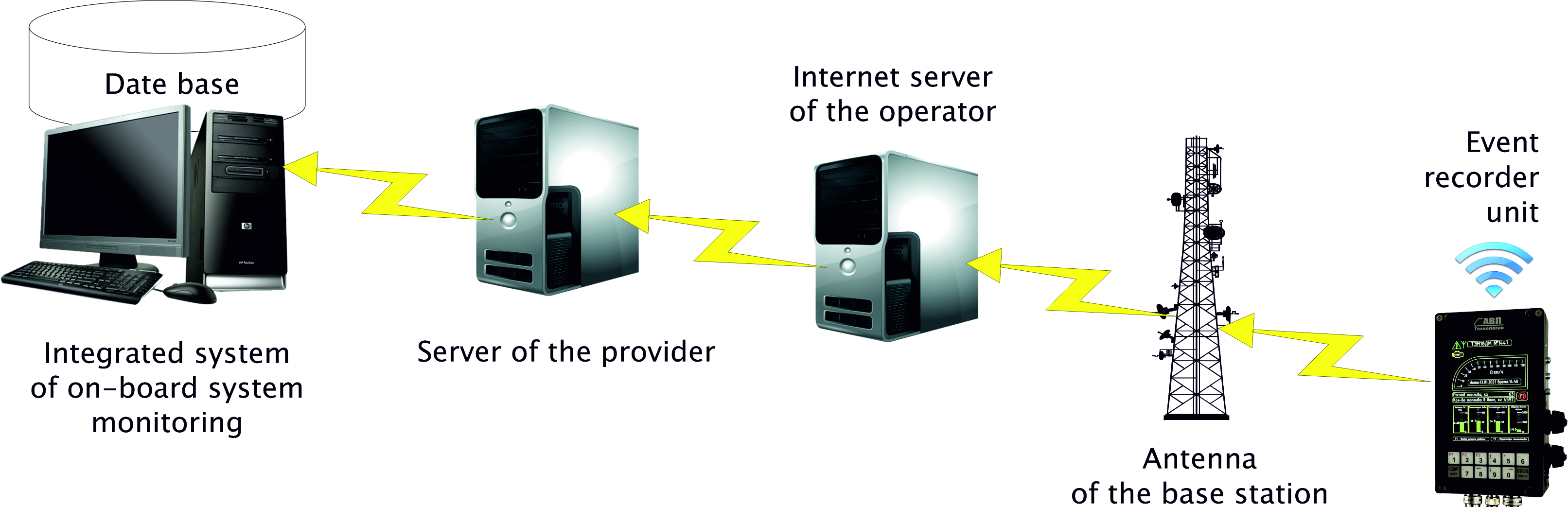

Transferring the information on server

Application effect components:

-

Reduction of up to 5% of fuel consumption and up to 2% of diesel oil;

-

Prevention of fuel stealing;

-

Increasing the accuracy of planning and consideration of fuel consumption;

-

Reduction of labor costs for the analysis of fuel consumption.

-

Enhancement of the quality of locomotive service based on analysis of recorded parameters, decrypted and obtained by special workplace.

-

Distribution of shunting locomotives for areas to optimize the operating modes in accordance with their actual technical condition in order to reduce fuel consumption.

-

Reduction of the harmful effects on the environment by lowering the emissions of harmful gases into the atmosphere.

|

Technical specifications

|

|

|

Power consumption, W, max |

100 |

|

Weight, kg, no more |

50 |

|

Range of measurement parameters |

Accuracy |

|

Fuel level measurement error, % |

± 0,25 |

|

Fuel density measurement error, % |

± 0,5 |

|

Fuel mass measurement error, % |

± 0,65 |